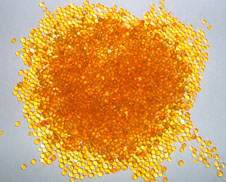

Beer Brewage Stabilizing Silica Gel

Brewery production of some corns and hops for beer is a universal process in beer industry. The quality of beer depends on its taste, clearness, color and foam retention, One of the key processes is the procedure of removing non-micro-organisms impurities. In order to have beer clear, we should use Silica Gel to remove proteins that make beer muddy.

Beer Brewage Stabilizing Silica Gel is a kind of non-crystalline micro-porous solid powder.Its chemical molecular formula is mSiO2.nH2O,insoluble in water or any other solvent (except the caustic alkali and hydrofluoric acid). It does not react with any acid, alkali or salt. It is nontoxic, tasteless,flame-resisting and non-explosive.It possesses high stability under hot or cold atmosphere and is harmless to human body,mainly used in beer industry.

Use

1. It has large specific surface area and numerous fine-pored structure.It adsorbs the proteins which cause beer turbid and removes them through filtering,just within several minutes, thus prolonging beer storage period by 180-240 days and keeping beer from being cold muddy.

2. It does not affect the beer foam or taste.Thanks to its superior physical and chemical properties,it does not have any adverse effect on the beer foam or taste.It generally recognized by the world beer industry.

3. It helps improve the filter promoting effect. It is chemically stable,contains no beer soluble substances,Its surface area and porous structure are both superior to diatomite.It is a kind of ideal filter promoter in aiding diatomite filter,making beer brighter and clearer.

Technical Data

|

ITEM

|

Specifications

|

Typical values

|

|

SiO2 (%)

|

98

|

98.7

|

|

Moisture Content (Wt. %) |

8

|

1.7

|

|

Particle Size (um, d50)

|

7-15

|

9.4

|

|

PH Value

|

5.0-8.0

|

5.6

|

|

Pore Volume (ml/g)

|

0.9-1.5

|

1.2

|

|

Specific Surface Area

|

300-500

|

435 m2/g

|

|

Heavy Metal (by Pb) %

|

0.003

|

<0.003

|

|

Lead (Pb)%

|

0.001

|

<0.001

|

|

Arsenic (As) %

|

0.0003

|

<0.0003

|

Efficacy

1. It has large specific surface area and numerous fine-pored structure. It adsorbs the proteins that causes beer turbid and removes them through filtering just within several minutes, thus prolonging beer storage period by 180-240 days and keeping beer from cold muddy.

2. Thanks to its superior physical and chemical properties, it does not have any adverse effect on the beer foam or taste. it is justified through practice that beer silica gel is the safest beer stabilizer. This is also generally recognized by the world beer industry.

3. It helps improve the filter promoting effect. It is chemically stable, contains no beer soluble substances. Its surface area and porous structure are both superior to diatomite. It is a kind of ideal filter promoter in aiding diatomite filter, making beer brighter and clearer.

4. It has a high selectivity, insoluble in beer, and can be removed after the last filtering.

Instructions

1. Beer Brewage Stabilizing Silica Gel is suitable for use on brewery production line equipped with diatomite filter. Likewise, it can be filled into the diatomite precoating tank and feeder of the filter.

2. Fill Beer Brewage Stabilizing Silica Gel in batches or continuously after fermenting and before filtering.

Filling in batches: Charges into the tank that is filled up with beer, keep adsorbing for at least 5 minutes. Beer Brewage Stabilizing Silica Gel can be totally removed during filtering.

Continuous filling: continuously fills into beer at the given amount and passes through a container that can maintain it a minimum of 3 minutes then to the filter.

Filling amount is 300-500 ppm (3-5MTs Beer Brewage Stabilizing Silica Gel /10000MTs beer). Filling amount can be determined by using "acceleration testing method", the method is also used to check the stabilization effect.

Take two bottles of beer and measure them with a turbid measuring gauge at the room temperature (the values measured are the initial turbid level), Soak the specimens at 0 Centigrade for 24 hours and then take the turbid value again at standard zero centigrade ; this value should not be higher than the initial value. It is referred as cooling turbid value.

Store the specimens at 40 centigrade for 3 days, put them back to water at zero centigrade for 24 hours and then measure with the turbid measuring gauge at standard zero centigrade, After that, heat them up again , repeat the procedure. During the measurements, if 3 EBC units are reaches, the strengthening test ends, The number of days at 40 centigrade multiplied by the factor 10 is then the actual number of days for fresh beer. it is considered far from enough just to do the above. What is more important is to check the air at the bottleneck for the specimens after the strengthening test. The air at the bottle neck of a half liter packing specimen shall be no more than 1 ml, Otherwise, due to the affection of oxygen, the results from the one with high air values will have to be got rid of.

The strengthening test at 0-40 Centigrade is considered to be the best way to be the best way to compare various stabilizers. It is proved through practice to be the most accurate. If the continuous fresh tests are to be performed, we then recommend that the strengthening test at 0-50 centigrade be adopted in which the number of days at high temperature is to be multiplied by the factor 20. " Delta H value" measuring method that is commonly used in beer industry may also be adopted.

Packing

15kg/polyethylene composite bag

Notes

1. Packing and size may be customized per your specific requirements.

2. When Beer Brewage Stabilizing Silica Gel is used, the amount of fine diatomite can be reduced appropriately depending on the amount of Beer Brewage Stabilizing Silica Gel being used, so as not to affect the filtering amount.

3. If you have any question and suggestions, please kindly let us know.